We have moved to...

BRIXHAM

We have relocated to Brixham –

Dart Sails and Covers,

Castor Farm Estate

Metherell Avenue

Brixham, Devon

TQ5 9QB

Please see below for details of our move and our latest newsletters:

Why…? Our current lease at Nelson Road is coming to an end and sadly will not be renewed.

What…? We have found a new loft which is 48% larger than our current one.

How…? We have secured a mortgage and invested in our own premises; this unit is ours.

Where…? Unit 1, Castor Farm Estate, Metherell Avenue, Brixham, TQ5 9QB

When…? We hope to move this Christmas, we’ll be keeping everyone informed as things progress. There is a lot to do between now and then.

Will you be open whilst this is all going on and during the move? Yes! We will continue to work from the Dartmouth site until the Brixham workshop is ready for us. We have a great team lined up to convert the Brixham site for us. In fact, it’s the same team that built our Dartmouth workshop in 2017. When the Brixham site is ready for us we’ll close for a few days and transfer everything across.

But you have some of my items, where will they be or go? Firstly, it’s not a problem, we’ll be taking everything with us. We have job tracking software which keeps us up to date with open jobs and where items are stored. The new unit also has a huge store; we’ll be loading everything up and taking it across once the unit is ready and stored on racks exactly as they are now.

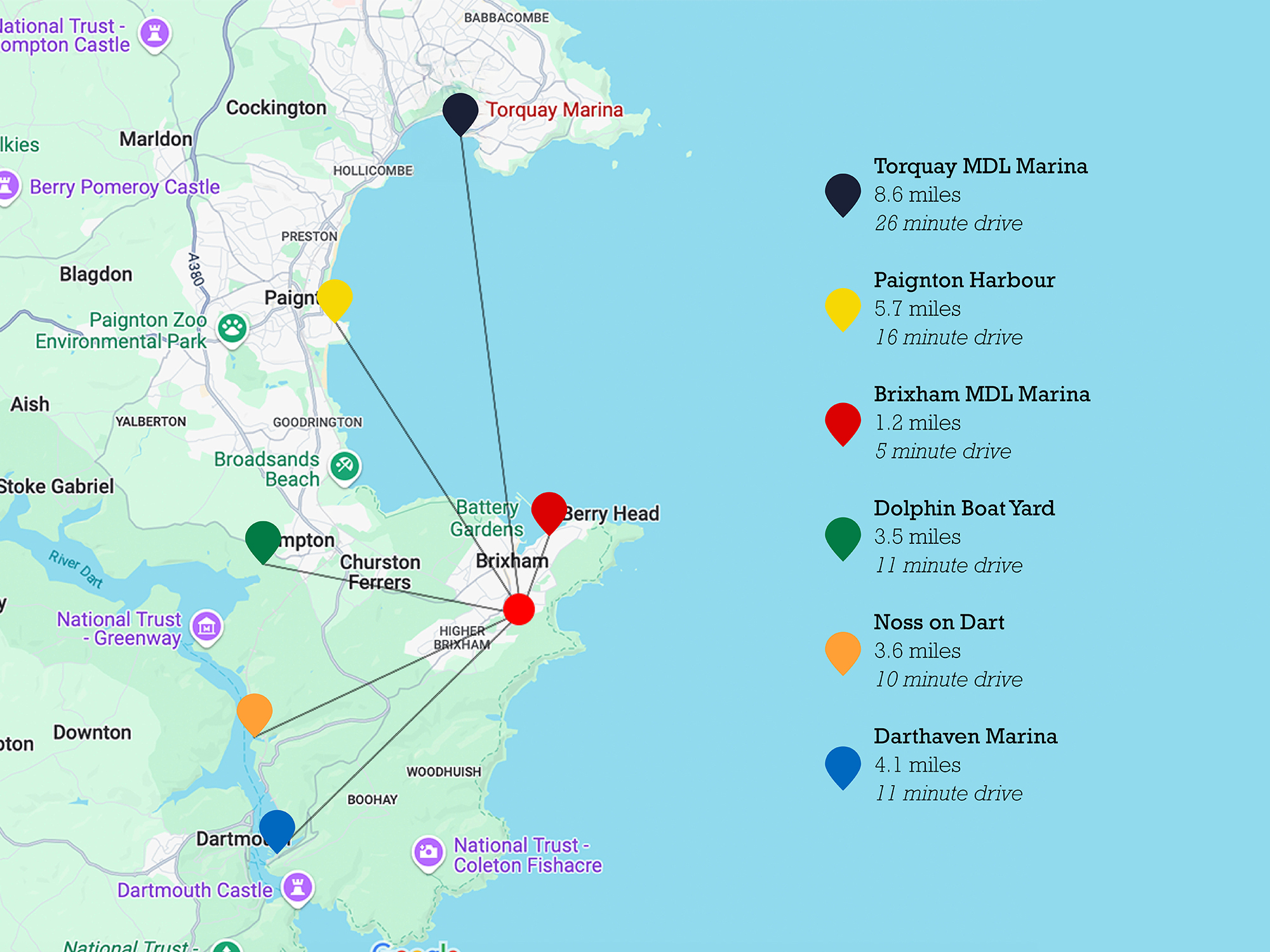

Brixham?! But you’re Dart Sails and Covers, “Brix Sails and Covers”? Yes, we know. If we could stay in Dartmouth we would, however when we investigated new locations it was decided that the East side of the Dart was beneficial as most of the local marinas are on the East side of the Dart. As we work throughout the south coast Brixham is the perfect location for us, and it’s hopefully closer and easier for most of you.

Metherell Avenue, is that the Sparks Studio? So, you’ve kicked out the kids? Yes and no. Unit 1 Metherell Avenue went up for sale on the 24th of April 2023, Sparks Studio still had one year left on their lease at this point, until July 2024. We placed an offer on the unit in June 2024 with the view of being an owner/occupier. The Surveys went on for longer than expected and it wasn’t until February 2025 that we had a revised offer accepted following the results of the surveys. We haven’t kicked anyone out; we purchased a unit which at the time of first offer had a tenant with a month left on their lease. As of February 2025, when the final offer was agreed, this unit came with vacant possession. We finally completed the purchase on 30th September 2025.

Who…? We remain the same team but hope that the increase in size enables us to look into adding to the team and maybe a couple of apprenticeships. Dom, Sean, Helen, Jamie, Mark and Laura can’t wait to show you our new loft.

What does this mean for me? Very little will change for us. This move is a big investment but as we own the unit, we have no lease, so we’ve set the length of mortgage and the payments. This has enabled us to set the monthly outgoings which are very similar if not less than renting elsewhere.

Can I help? I think we have everything covered but the most important thing for us is going to be cashflow during this process. If you have been thinking about treating yourself to that new sail or cover, we’ve never appreciated every order as much as we do now; every order will make a difference to us. We’d also really appreciate our invoices being settled in reasonable time; we ask that invoices are please settled within two weeks. It’s not uncommon for some of our invoices to be left unpaid for months. If you have your own cash flow to work around, then please talk to us.

How do I get in touch with you? Dominic and Seans mobile numbers remain the same and we all receive emails sent to info@dartsailsandcovers.co.uk.

Dom – 07773 909206

Sean – 07717 500726

We intend to take our landline number, but we assume there will be a period where this is disconnected. Please see our “meet the team” page on our website for our individual contact details.

Finally, an apology.

This hasn’t been an easy process, we have been distracted with valuation surveys, structural surveys, asbestos surveys, drainage surveys, planning permission, builders, roofers, financial advisors, solicitors etc. We know that a few enquiries have slipped through the net and response times have been too long. We really appreciate everyone’s enquiry and custom. To those that have received poor service we do sincerely apologise and to those that persevered and tolerated us, thank you!!!

We are working hard to get on top of things as fast as possible.

The story so far…

Hello again, we can hardly believe that a month has already passed since getting the keys to our Brixham workshop. It’s been a busy few weeks and a lot has changed.

Here’s the story so far, what we have done and why?

Outside/Garden

The site had been neglected for some time; the outside had got to the point of being out of control. A hedge trimmer was needed on day one to cut through the foliage and find the entrance gate. One of the main priorities has been sorting the leaking roof which needs scaffolding and space to erect this. It was decided that it was best and most cost effective to clear the entire site in one go and to fell the rotten sycamore at the main entrance too. It’s a shame to see it all go but it’s all clear now and ready for scaffolding.

Before…

After…

Inside

This unit was once a JW Kingdom Hall that had been set out to suit their needs. It came with four toilets, a kitchen, a changing area, some odd shaped rooms and a hall with a stage. These things aren’t really needed or helpful for making sails and covers, so we have removed everything and gone back to the concrete floor and block walls.

Before…

After…

The plan is to copy the design of the Dartmouth “box” which housed the entrance, a design office, kitchen and toilet. The stud work box in the corner worked well and maximised the space left for our workshop/sail loft.

Dartmouth Loft “Box”

Dartmouth Loft

At the moment things are going well, and a plan has come together. The roofer and builder need around 6 weeks to do their thing which means it should be ready for us mid/late December. The plan is that we carry on working from our Dartmouth loft until Christmas, then pack up the work bench, machines, tools etc. Move over to Brixham between Christmas and New Year and open the doors to our new workshop in Brixham Monday 5th January, easy as that!

For now, that’s all we have, keep an eye out for the next one which you don’t want to miss.

Plan B

No plan survives contact with reality – or the Great British weather, which is much the same thing.

Hello again! We’re edging ever closer to the big move now; the team has been working flat out to keep things on track. Here’s an update on what we’ve achieved over the past four weeks, why we’ve shifted to Plan B, and how everything is shaping up.

INTERIOR STRIP

The team did an outstanding job stripping out the interior in just four days. Yes — four days! We were handed back a completely empty shell, ready for the next phase of prep.

The walls needed all the old dot-and-dab adhesive removed before painting, while the floor had to be cleared of its previous glue. The walls were relatively straightforward — one solid day of scraping, wire-brushing, and sanding had them ready for primer.

The floor, however, was another matter entirely. It needed hand-scraping to remove the tacky residue, followed by repeated rounds of sanding… day after day, evening after evening. Tough work, but absolutely worth it for the finish we’ve ended up with.

During the stripping out of the interior

All stripped out with the finished floor!

THE ROOF

The asbestos roof had simply reached the end of its life. We could have tried patching it, but realistically it was on borrowed time — and removing it later, with a full workshop and machinery underneath, would have been almost impossible.

So, we bit the bullet. The entire asbestos roof has now been removed and replaced with a modern insulated system. The building is fully watertight and incredibly well insulated (280 mm / 11 inches), which should help keep winter heating costs under control.

The old roof

During the installation

The new roof

The roof was one of the major components of the project, and naturally the weather stepped in right on schedule to complicate matters. What was supposed to take eight days took the full eight plus an additional four-day return visit to finish the job. This has knocked the timeline back, leaving the builder with two fewer weeks than planned — hence the move to Plan B.

Plan B

With the schedule tightened, the builder will now only have time to complete the reception, offices, kitchen and toilet areas before Christmas.

The workshop and loft floor will be tackled in January, which means we’re anticipating 2–3 weeks of downtime early in the new year before we’re fully up and running in the new space.

We will remain fully operational in Dartmouth until Friday 19th December. After that, we’ll begin dismantling the workshop, packing up the machines, and moving everything across to Brixham.

Our focus now turns to the final details — phone lines, post, internet, and all the other essentials that make the place function. There’ll be another update over Christmas, hopefully confirming everything is still on track and sharing the final pieces of the puzzle.

A huge thank you again for everyone’s patience and support throughout this process. We can’t wait to welcome you into the new facility once it’s complete.

Closing One Chapter, Building the Next

Hello again. We hope you enjoyed the Christmas festivities and managed to take a well-earned break from winter boat maintenance plans.

As the year draws to a close, we’d like to thank you all for your continued support, custom, and trust. This has been a significant year for us, marked

by the purchase of our own building — something we simply couldn’t have achieved without you.

Owning our own home gives us a solid foundation to continue doing the work we love, while supporting your future plans, trips, and adventures for many years to come.

“The Box”

As mentioned in an earlier newsletter, we’ve stuck with a wooden box design to house the entrance, offices, kitchen, and toilet. This layout worked extremely well in our Dartmouth loft, as it maximised the workshop area and allowed us to create the largest possible loft floor.

We’ve carried this concept across to the new space, creating a welcoming entrance area, two offices, a kitchen, and a toilet, while keeping the workshop open, efficient, and focused on what matters most.

The new box layout

“The Wine Cellar”

We’ve also opened up the stairs to the downstairs store. Once complete, this will be a south-facing, fully plastered and heated space, racked out specifically for winter storage.

The new store is large enough to provide more than double the racking capacity we had in Dartmouth — a significant step forward and a hugely useful space for us going forward.

The new “wine cellar” storage

Leaving Dartmouth

As we prepare to leave Dartmouth, it’s hard not to feel a real mix of emotions. This has been our home for a long time and the place where so many sails were cut, repaired, and finished, and where many of the relationships we value today were built.

The loft’s last fully operational day was Tuesday the 23rd of December, marking the end of a chapter that has meant a great deal to us.

On the 27th, we began packing up the Dartmouth workshop, starting with the bench/raised floor. We intend to reuse as much of this timber as possible, so it has been carefully dismantled to allow the builders to reassemble it efficiently in the new space.

Packing up…

Looking Ahead

As we turn our focus to the weeks ahead, our priority is getting the new loft up and running as smoothly as possible. The plan is for the new floor/bench to be built during the first week of January, with the second week used for varnishing the floor, installing the machines into their pits, and transferring all sails and covers currently in storage into the new storage room.

During this early part of January, we’ll be split between Dartmouth and Brixham, with plenty of van trips back and forth. We’ll absolutely still be around, but we appreciate your patience while we complete the move.

While there is still work to be done, we’re excited about what this new space will allow us to do — improving efficiency, increasing capacity, and continuing to deliver the quality and service you expect from us. We look forward to welcoming you into the new sail loft in the new year and sharing the next stage of the journey with you.

A Quick Note on Contact Details

One small issue we’re currently dealing with (and hoping will be short-lived) is that the new site does not yet have fibre-optic internet installed. This should be resolved very soon.

As our phone system has been internet-based for several years, we’ll be keeping the same number, but we may be without our landline for a short period until the connection is live. In the meantime, the Contact Us page on our website lists our mobile numbers and email addresses should you need to get in touch.

There will be one final update like this in January, hopefully confirming that the move is complete and setting out our confirmed contact details. Please keep an eye out for it.

Thank you ever so much once again for 2025 — we can’t wait to see you in 2026.

We’re home –

Welcome to our new loft in Brixham

Hello again. We’re delighted to finally be able to confirm that our move to Brixham is complete.

Our new loft is finished, the team has settled in, and all machines are now fully operational.

You can now find us at:

Dart Sails and Covers

Castor Farm Estate

Metherell Avenue

Brixham

TQ5 9QB

We’d like to share with you what we’ve been up to over the last couple of weeks — how we’ve done it, and why.

Entrance

Possibly one of the best decisions from the rip-out was to carefully take up the existing “dance floor” left by the previous occupants. This oak-effect laminate flooring has been piled up in the way for weeks, but was finally put to good use and re-laid in our entrance and offices.

The fresh plaster has been painted white and trimmed with navy skirtings and architraves, colour-matched to our logo.

Loft Floor

The design for the new floor mirrors the previous one. Dwarf walls were built from 4” x 2” timber to support the 8” x 2” floor joists, with MDF used to cap the structure. MDF absorbs our spikes rather than popping, as chipboard or ply tends to do.

We reused almost every piece of timber that came out of Dartmouth — including all the noggins — some additional lengths were required, as the new loft floor has increased in size by just over 35%.

Heating

Unfortunately, we’re not yet connected to gas, but the building did come with an old oil heating system. Local legend “Duffy” happens to be a specialist in these systems and, within a couple of hours, had it serviced, combustion checked, the air shutter ram replaced, and the system fired up and working.

For now, we have radiators in the sail store and entrance/offices. We plan to refit our Powermatic gas heater later in the year ready for next winter, but for now we have more than enough to see us through to spring.

Electrics

The electrics required a complete start from scratch, but with a temporary setup along the way to allow power for lights and tools as the build progressed.

Energy-efficient LED lighting has now been installed throughout, modern breakers fitted in the consumer unit, along with a new fire alarm system, sockets and switches.

Thank you

We’d like to take this opportunity to say a few thank yous.

Firstly, thank you to everyone for your patience and understanding while we’ve gone through this process. It really means a lot that you have trusted and supported us throughout.

Thank you also to everyone who has settled their accounts promptly — it has made a huge difference to our cashflow and has genuinely helped reduce the pressure during a very busy time.

Matthew – Coppertops Tree Surgery – https://www.coppertopstreesurgery.co.uk/

Matt and his team arrived the morning after we purchased the building and immediately attacked the out-of-control site from one end, not stopping until they reached the other. What looked like a jungle was quickly, safely, and completely cleared in just three days — an epic task carried out with a smile.

An absolute dude who just got on with it.

James – Mr Builder Co – https://www.mrbuilderco.com/

James came in on price and on time every time during this project — from the rip-out, to the box build, to the loft floor. He and the team are exceptionally hard-working, with a proper can-do attitude. Nothing was ever a problem, and practical solutions were found to every issue.

Darren Blackaby – DB Roofing Services – https://db-roofingservices.co.uk/

Darren was the only person who didn’t suck his teeth when asbestos was mentioned. He actually assisted in steering us towards a Land Remediation Relief claim, which will eventually help towards the cost of the replacement roof. Funnily enough, the Revenue aren’t quite as keen to give as they are to take — but one day we may get something.

Sam Owen – SO Electrical – 07833453671

How he connected what looked like a snake’s wedding of cables and made it all work I’ll never know.

“You need a tray, mate — it’s so easy with a tray.”

From POE cables to last-man-out switches and AFDD protection, Sam had it covered. On time, on price, and extremely knowledgeable. He completely understood what we wanted from day one and made it happen, without a single issue being left unresolved.

Quite simply, we don’t believe this project would have been possible without these four key people and teams.

Looking ahead

This move marks more than just a change of address for us. This larger builder has increased our overall floor area by just under 50% which has enabled us to build a new loft floor which is 35% larger than our previous one.

The new space gives us the room and layout we need to work more efficiently, invest in better processes, and continue delivering the level of quality and service you expect from us.

We’re incredibly proud of what’s been achieved in a short space of time, and genuinely excited about what this new chapter allows us to do next. Thank you again to everyone who has supported us along the way — we look forward to welcoming you to the new loft very soon.

For now…

That’s it. Well, I guess so — for now at least. We’ll be back to being sail and cover makers.

There are already some future plans quietly in place which may be carried out over the summer. For example, 8” x 2” joists have been installed in the office ceiling ready to take a future upstairs floor. There’s also work to be done to the car park, and at some point we’ll need Wales & West to “dig up the road” for a gas line.

(Sorry — this is one of Sean’s favourite Peppa Pig quotes, which we used to hear all the time.)

For now though, we’re exactly where we need to be. The space works, the team is settled, the machines are running, and we’re back doing what we do best.